I’m sharing my startup stories while building out my latest project – Calenzen – which seamlessly reformats meetings in your calendar so you can always instantly click to dial. No special apps, calendar programs, or software is ever needed. Learn more about Calenzen.

The Problem

As an avid cyclist and technology buff, I was naturally among the first to get a GPS computer for my bike. This was back in 2008 and the Garmin Edge showed all the typical cyclometer statistics like speed, distance, etc. In addition, it also included a moving map so I’d never get lost again!

While the GPS was a great tech advancement, the plastic clip used to mount this onto my bicycle was easily broken through regular use. Replacements were available directly from the manufacturer for a premium price of $15 or more. This seemed quite steep for such a simple accessory, especially one that was prone to breaking through normal use.

How hard could it be to manufacture my own replacement? Is there any way I’m the only person frustrated by this design failure? Herein began my second e-commerce journey and an exciting first foray into custom manufacturing.

How I Got Here

Discovering a problem, in and of itself, is not sufficient to start a business. However, this came on the tail of me winding down the textbook shipping business.

There was ample opportunity to use some of the same software and skills already developed to run this at scale. Even better, I could instantly overcome the two biggest drawbacks to the textbook business – high cost of goods sold and lack of control over distribution. Both of these contributed to a much lower risk profile.

Manufacturing the Bike Mounts

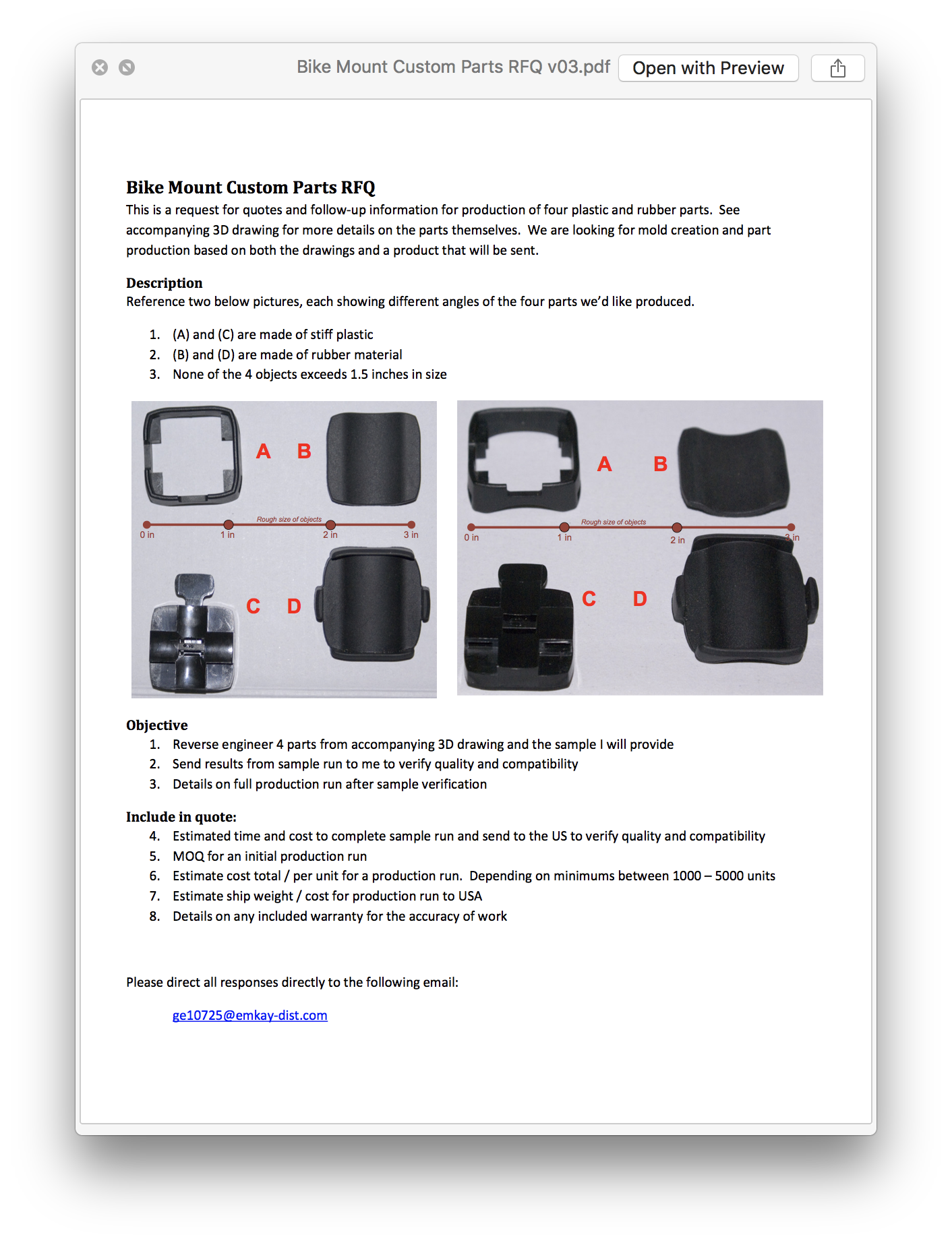

Armed with several sample prototypes of the compatible bike mount, I began the process of getting quotes from manufacturers. I quickly found out that sending samples for each quote was too time consuming and was becoming expensive.

Therefore, I put out a bid request on Elance (since acquired and renamed Upwork) for a set of SolidWorks compatible 3D CAD drawings of the reference prototypes. Less than a week and $200 later, I had drawings in hand and was ready to find a manufacturer.

I scoured Alibaba for viable manufacturers and shared my digital request for quote (RFQ) among all the promising candidates. The responses quickly rolled in, but with each one I became even less confident in the entire venture. To start with, there were so many variations between the responses that I couldn’t even form a baseline. To make matters worse, my success communicating with them was mixed in the worst way – the best manufacturers on paper didn’t seem like personable partners, whereas the sketchiest proposals came from the most responsive and credible manufacturers.

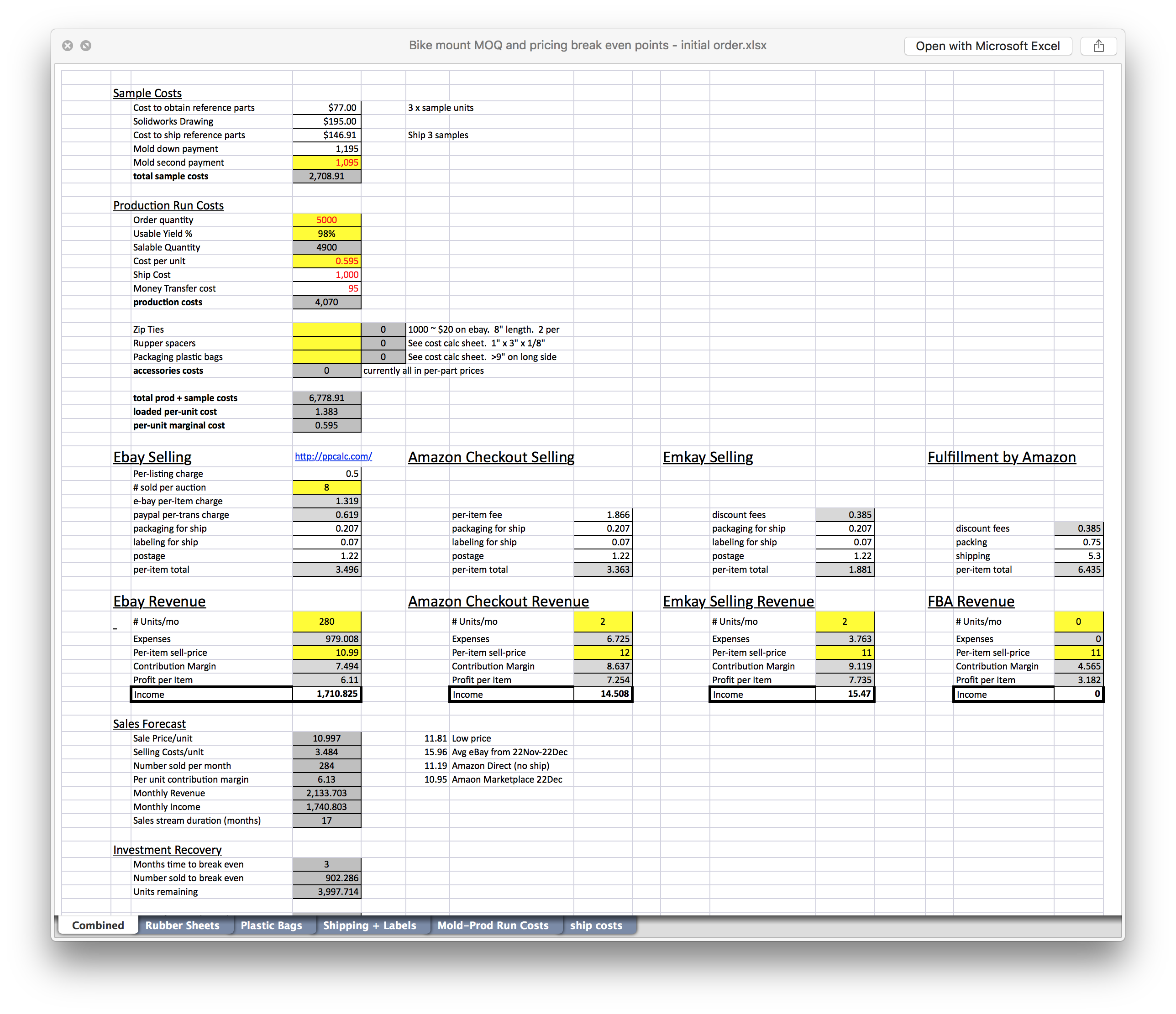

The manufacturer proposals contained two primary components. The first component was the actual cost for the production run, while the second was a quote to create the molds needed for the plastic parts. This was a one-time cost and needed to be paid regardless of the production run size or even if the sample-run passed inspection. One-time mold creation costs were across the board, ranging from two to over 13 thousand dollars.

After a weekend of soul-searching and running the scenario past a few mentors, I came to a final decision. Given all the uncertainties, I would proceed with the lowest cost option. If my money was stolen or if the molds turned out to be useless then the total loss on my investment would be much lower. Additionally, if the sample-run was close to acceptable then the additional investment needed to bring everything into compliance would be minimized.

To think of it another way, I could either lose a small investment if I was being played and have three or more tries to get it right for less than the quoted price from the other manufacturers.

That Monday, I wired the manufacturer money to start and shipped off physical samples of both the prototype and one of the Garmin GPS computers so they could verify sample functionality directly.

After a few weeks, the first samples were on my doorstep and they were a perfect reproduction. On my command, the full production run commenced and was ready to ship before the end of the month. That presented yet another hurdle to overcome.

From Manufacturer to Me

I was anxious to get my hands on the product and start bringing in revenue. At the same time, I had no idea how to get the product all the way to Minnesota. My solution was to split the shipping and send the bike mounts via both air and sea.

Shipping by air was more expensive, but so much more predictable. The entire process was the same as any consumer shipping I’d used in the past. I had a tracking number to follow and within a few days, DHL had dropped five boxes on my doorstep. I immediately unpacked the boxes, verified they matched the sample runs, and started my sales machine.

The remaining units were shipped by sea free on board (FOB). This meant the manufacturer was responsible for the shipment until they reached the ship. Once the ship left port, I was fully responsible for all the moving parts needed to get them inland.

I arranged for a customs attorney to file the right paperwork while the items were in transit. Thankfully, I met a critical deadline to get everything filed and certified at least 48 hours prior to the ship’s arrival in port.

The same attorney also helped me get the remaining 25 boxes of bike mounts onto a train and shipped to the nearest Koch distribution center in Minnesota. Once I got the arrival notice, I drove my truck into their yard, backed into the loading ramp, and filled it to the gills with box after box of bike mounts.

Finally back at my house, these boxes took up an entire wall of the garage. This was valuable real estate and I needed to start selling product quickly!

Selling Time – Front Office and Go to Market

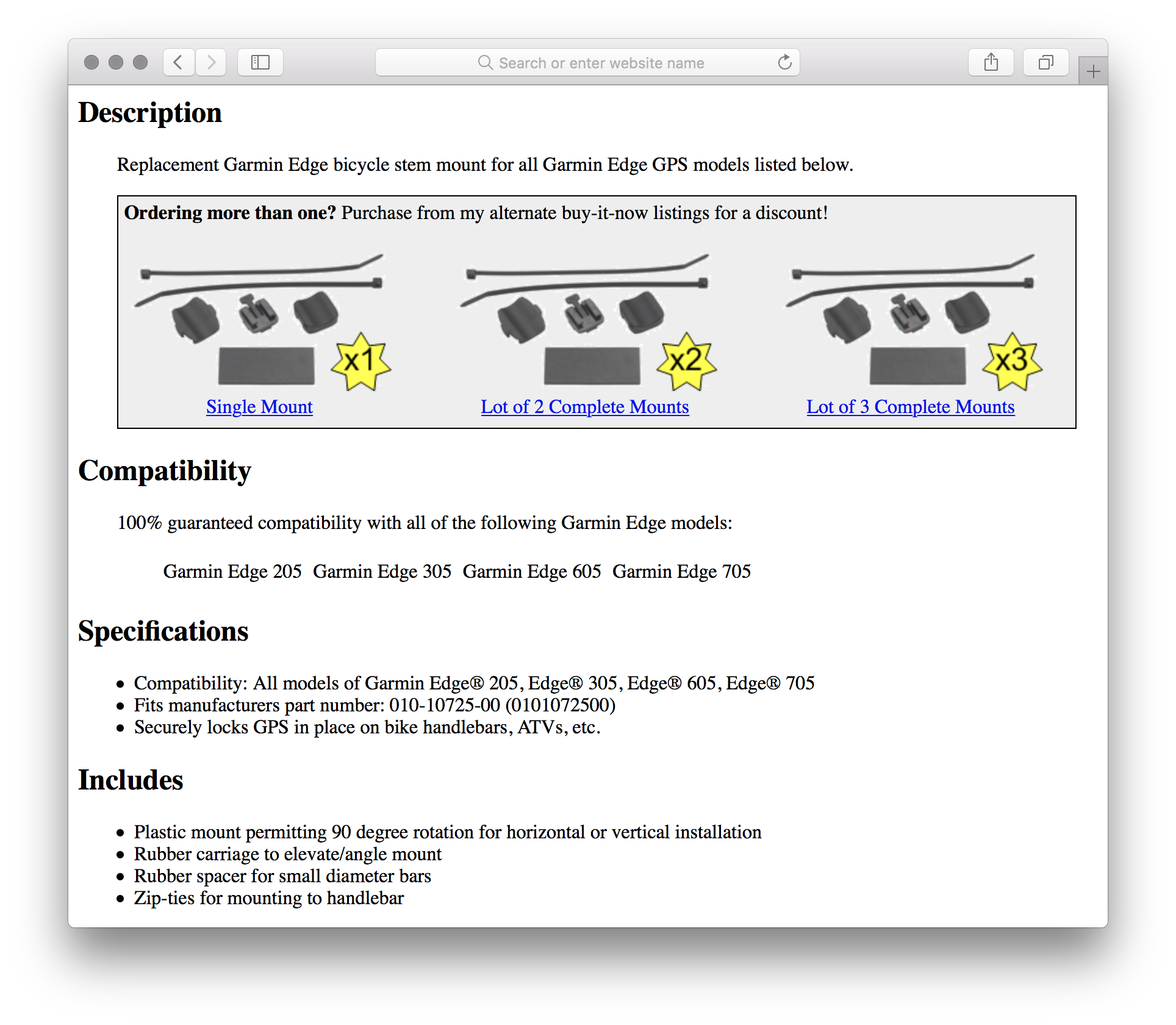

I had three primary sales channels for this product: Amazon Marketplace, eBay, and directly from my e-commerce website. Surprisingly, very few sales came through Amazon. Were I to restart this venture now rather than in 2008, the results may very well be different.

Given the low sales volumes from Amazon, I never completed the integrations needed to fully plumb those orders into my logistics pipeline. Therefore, each order required manual steps to capture customer information from Amazon and to populate status to Amazon. This was different from the Garmin supplied mount therefore I could not piggyback on that listing. Creating and listing an entirely new product on Amazon was challenging and I believe search results at the time discouraged it.

Sales from my web site were steady, especially given my continued dependence on Google’s Froogle service to direct a slow but steady stream of customers who were ready to buy on first click. PPC advertising was still relatively inexpensive at the time, but there was really no need to invest in it when top of page results placement came for free from Froogle.

The overwhelming majority of sales throughout this two year venture flowed through eBay. They offered a middle of the road transaction fee (less than Amazon, but substantially higher than direct sales). More importantly, they offered easy discovery from customers ready to buy and I was able to optimize a number of listings to encourage larger sales and repeat buyers.

One early optimization for eBay listings, was to cross-sell and offer higher quantities at a discount. At the time, eBay didn’t have any such functionality built in. I was able to create it by adding unique words within my listing and then use HTML links at the bottom of my listings to search for those keywords.

Without this tweak, I would expect the majority of orders to be for a single replacement unit and that’s exactly what I saw across my other channels, especially through Amazon. eBay sales were much different however, with well over half of all orders opting to purchase two or three bike mounts for a slight unit-price reduction. Customers got more product and I increased revenue with almost no change to fixed costs like PayPal transaction fees and shipping costs.

Delivering Product – Back Office Logistics

The optimizations that enabled care-free scaling with my textbook venture were top of mind when designing a system for managing these bike mounts. Given the much smaller per-item revenues associated with the bike mounts, I didn’t want to give any standard order special focus in time or effort. This laziness, of course, worked far better when the distribution and ship center weren’t in my garage.

I broke the solution into three primary components – order ingress, postage, and pick-and-pack for shipping. Everything that required thought was automated and implemented fully in software, while the physical activities were designed to be foolproof.

All orders started when I received payment. Direct orders through the web site were active as soon as the I captured the customer payment. Orders from eBay were captured as soon as PayPal sent a webhook (they called it an IPN at the time – instant payment notification) indicating a completed payment. The IPN webhook included transaction numbers, eBay auction details, customer name, and ship addresses. Regardless of how the order originally sourced, the data was consistent and ready for moving to the next step.

The second phase of the ordering workflow was to obtain postage. All orders were shipped in a padded envelope that had enough room for up to three bike mounts. I knew the weight of an empty envelope and the weight of a single bike mount. Given the order size, I used a quick knapsack algorithm (link) to allocate the right number of bike mounts per envelope. If there were three or less bike mounts in the order, it shipped in a single envelope. If there were more, I’d use additional envelopes in multiples of three. By keeping the shipping unit completely standardized, I was able to simplify both the postage and the shipping components of this workflow.

At the time, there were no price competitive postage services with API access and this presented a problem. It ended up that Stamps.com offered a Windows tool that accepted batch jobs from the command line and could capture data from a referenced template file. I hooked a Zebra label printer to a Windows workstation in my garage and with a quick script to poll for orders ready for shipment, I had the postage problem figured out.

The final step in the workflow was picking and packing for shipment. This same label printer would output a packing list. It showed the order number so I could always confirm a match between the postage and packing slip.

The whole family got involved with picking and packing. Every time someone was near the printer and noticed a few labels had printed, they would quickly pack them up ready to ship.

With each change in the order workflow – from new order received, postage printed, to shipping – customers received an email showing the updated status. Even after adding generous delays and business-hour-only processing time to make it feel like more high-touch work was being done, this would typically complete in well under an hour.

Business Life Cycle

I ran through two full production runs of the bike mounts. Sales slowed during the final few months as the GPS unit that required the mount was no longer being manufactured. In an effort to quickly close out the last of the inventory, I held my first one-day sale.

I sent an email to every customer I’d had the previous two years and let them know about how to purchase directly from my website for a great bargain. Sales that day were so high, I ran out of inventory and needed to carry several boxes of envelopes to the post office for shipping.

Lessons Learned

I believe it was dumb luck to stumble on a product with such a pent up demand for a higher quality generic replacement. I spent weeks after winding down the sales of this bike mount trying to find other similar items. I searched through eBay sales and search history then ran back of the envelope calculations for manufacturing cost and ability to meet revenue targets. Nothing presented itself as an opportunity with a similarly small risk, ability to manufacture, and ease of shipment. Were I to identify another suite of products, then this entire venture could be spun back up to profitability.

There was enormous risk in the manufacturing steps. To this day I have no idea why the prices for molds varied so much and who was scamming who (maybe the others accounted for quality problems in their initial bid? Or were they expecting aggressive price negotiations?).

The best part of this entire venture was being in full control of the distribution chain and the very low cost of goods sold. The bike mounts sold for about $10 each and cost of goods sold was well under a dollar.

With these numbers, my immediate response to every customer satisfaction issue was to send a replacement unit. Item didn’t arrive? I’ll send another. Item broke? I’ll send another. After thousands of units sold, my ratings never contained a negative response.